Not all pumps are created equal. If you ever went from an old rotary pump that needed both hands to operate to a top-of-the-line electric unit, you know that the right tool makes all the difference.

There are many pump mechanisms available for a wide array of products; they all have pros and cons, and it’s important to find the right pump for your needs. Let’s take some of the most popular pumps in the MÄKTIG inventory and see what makes them tick.

The manual way

The simplest pumping mechanism is probably the lever-action; as the name implies, moving the lever up and down actuates a cylinder that pumps fluids from the reservoir to the nozzle. Units like the Compact Lever Grease Gun (PART # 600028), the Plastic Lever Pump (# 601030), the Lever-Action Barrel Pump (# 600541) and the Grease Filler Pump (# 600450) all use this mechanism. While lever-action pumps are inexpensive, simple to operate and can work in hostile environments – such as freezing cold or rain – they require a lot of effort from the user.

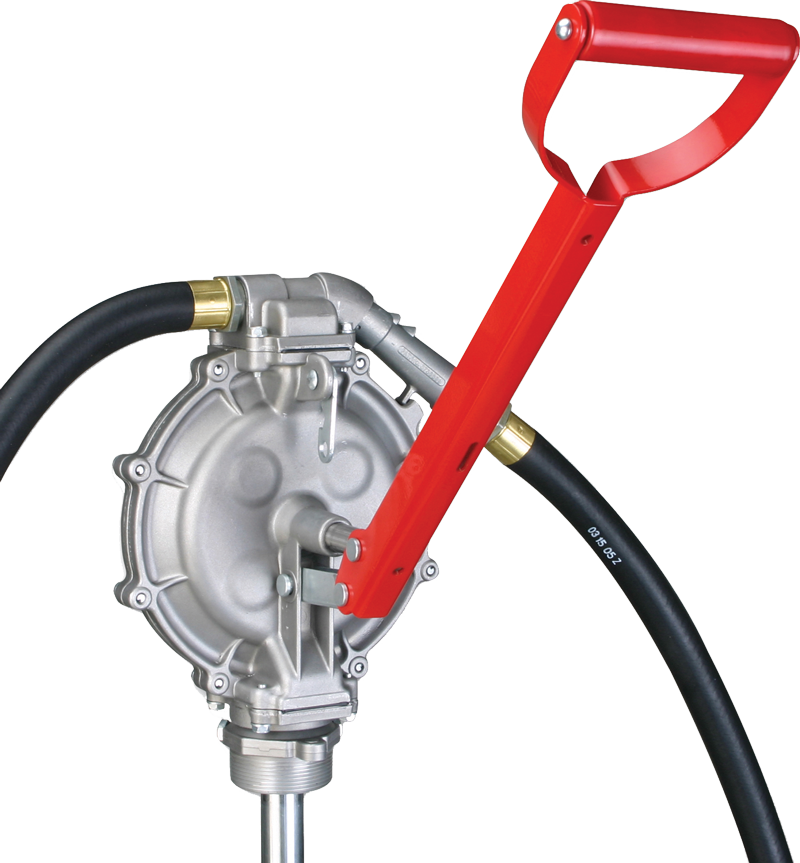

Rotary pumps are another type of manual unit you may encounter. Instead of moving a lever up and down, you simply rotate a crank. For media like Diesel Exhaust Fluid, fuel and water, cranks work much faster than lever pumps. MÄKTIG has many rotary pumps for various applications; these include the Industrial Rotary Drum Pump (# 601062) and the Plastic DEF Rotary Pump (# 600548). The rotary unit has another advantage up its sleeve, too: it is much more precise than a lever-operated cylinder. Here’s an example: the Quart/Litre Stroke Pump (# 601063) dispenses exactly one litre of fluid per stroke.

Harness the elements

If you want to move large quantities of fluid – or don’t want to manually operate a pump all day – MÄKTIG can harness two distinct physical forces to help you: compressed air and electricity.

With products like the Air-Operated Grease Gun (# 600050) and the Air Operated 50:1 Grease Pump (# 600460), you simply need to connect a compressor or an air tank via the female 1/4 NPT fitting to get constant pressure through your nozzle. If you need to lubricate industrial machinery on a daily basis, these pumps are for you.

Need flexibility? Go electric and cordless.

Don’t have a large air compressor nearby, or simply don’t feel like hauling that heavy tank around the shop? Then consider an electric pump. While you could get a corded unit that plugs into a wall outlet, MÄKTIG has something better. Check out the Cordless Electric Drum Pump (# 601625). It’s powered by a 19.2V Lithium-Ion rechargeable battery and can deliver up to 410 L of liquid on a single charge.

You can find all these products -and many more- at Bumper To Bumper stores and Auto Part Plus stores.